Kündig Technic Botop

Meeting the Output-Driven Demands of Industrial Sanding Applications. Balancing the Imperatives of Swift Feed Rates and Superlative Surface Finish Quality is Paramount. At Times, Achieving Both Objectives in a Single Pass Becomes Essential. Enter Kundig Top and Bottom Sanding Machines – Your Solution to Simultaneously Fulfilling These Demands.

Working widths are:

- 650mm

- 1100mm

- 1600mm

- 1900mm

- 2200mm

Choice of sanding heads includes:

- Cross belt

- Cutterblock

- Callibration roller

- Pad unit

- Combi Unit

- Electronic pad

- Combi incorporating electronic pad

- Can be produced with traditional or Oblique sanding heads

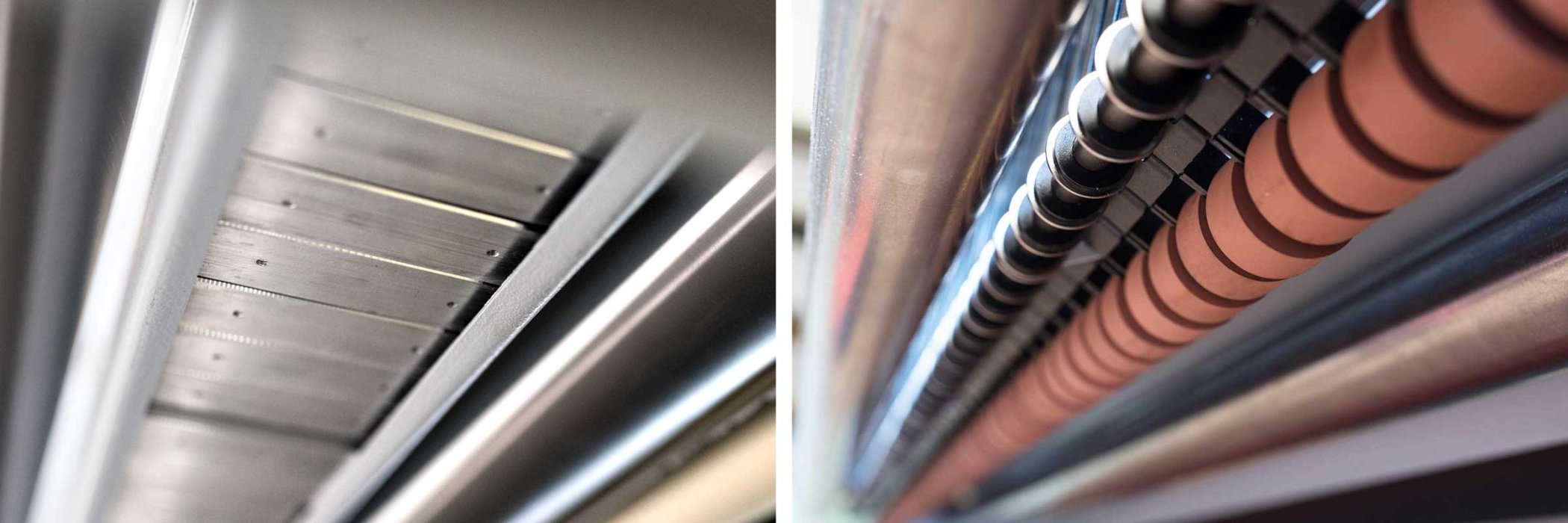

Sanding Pads

Pneumatic Pad

Well proven sanding pad technology, especially for solid timber processing. A continuous air cell provides even pressure on the workpiece.

Segmented Pad

The segmented pad is divided in segments either 35 or 22 mm wide. These segments are computer controlled and preferences can easily and thoroughly be adjusted by the operator. The electronically controlled, segmented pad is especially useful for taking care of those delicate workpiece edges on lacquered or veneered parts.

Pad Options

Segments and therefore the sensing rollers at the machine entry are available in 35 or 22mm width. Depending on the material that needs to be sanded, a variety of sanding shoe hardnesses are available. Two different hardness shoes are included from the factory.

Units

Our Botop series of wide belt sanders offers the convenience of double-sided processing in just one pass and combines it with options of parallel sanding or the Kündig exclusive oblique sanding technology. This technology has a variety of advantages: Vanishing of sanding traces on the work piece, longer belt life span, less fiber-raising and therefore much finer surfaces and less lacquer consumption.

Top and bottom sanding units are available as planers, brush units, calibration rollers and sanding pads, either pneumatic or segmented and electronically controlled. They offer, as usual, a very stable support, high precision build and above average life span. For high output applications and the heat build-up that comes with them, there are different belt lengths of 1900, 2000, 2620 and 3250 mm available.

| Calibration Roller R | Calibration Roller G | Calibration Roller Rd | Sanding Pad P/E | Pneumatic Pad Pd | Electronic Pad Ed |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Calibration Roller | Large Calibration Roller | Calibration Roller oblique | Sanding Pad electronic or pneumatic | Sanding Pad oblique pneumatic | Electronically controlled segmented Pad oblique |

Options

|

Enormatic

The machine measures workpiece thickness and starts the sanding process automatically. |

|

Touch Screen

The operator can choose between automated and customisable quick start programmes and manual operation adjusting all the relevant parameters.

|

|

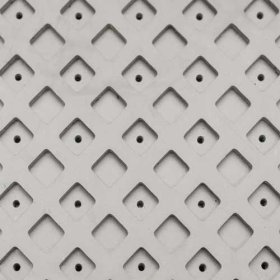

Conveyor Belts

|

|

Lacquer Package

|