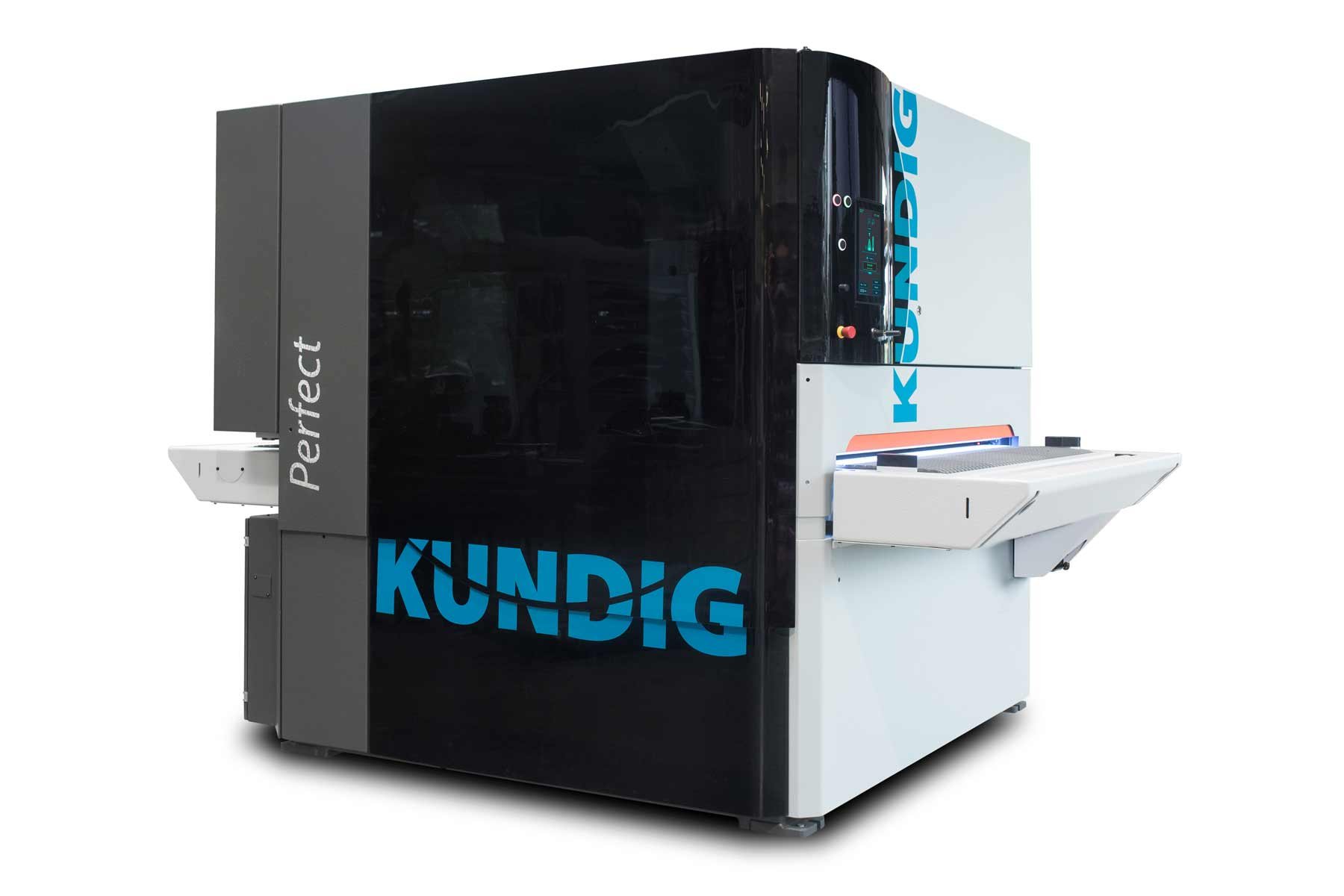

KÜNDIG Perfect

The KÜNDIG Perfect conceals a myriad of innovations in sanding technology. These innovations, when combined, surpass even the most stringent demands for surface quality. The control unit, developed from the ground up, simplifies and streamlines the sanding process. All our models are compatible with integration into any relevant control system, making them fully Industry 4.0 capable. Naturally, the Perfect is entirely modular and can be equipped with a wide selection of sanding units and options.

Key Features

- High-speed technology for exceptionally fast feed speeds.

- An extensive range of options and customization possibilities.

- The most advanced control unit for sanding machines.

- Capability for belt and workpiece cleaning without the need for compressed air.

- Automatic pressure control for segmented pad.

- Electronic grain adjustment and distribution of stock removal between contact rollers.

- Pattern/vintage sanding (with cross belt), among many other features.

Effortless Operation

For decades, designing operator-friendly sanding machines has been a primary focus at Kundig, ensuring that they can be used comfortably by almost anyone, regardless of experience.

- Manual Operation: Our sanding machines can be fully operated manually using just three convenient control elements.

- Comfort Operation: Thanks to the Enormatic function, Kundig sanders can be easily, reliably, and very comfortably operated. Workpiece thickness measurement and the initiation of the sanding process are executed automatically.

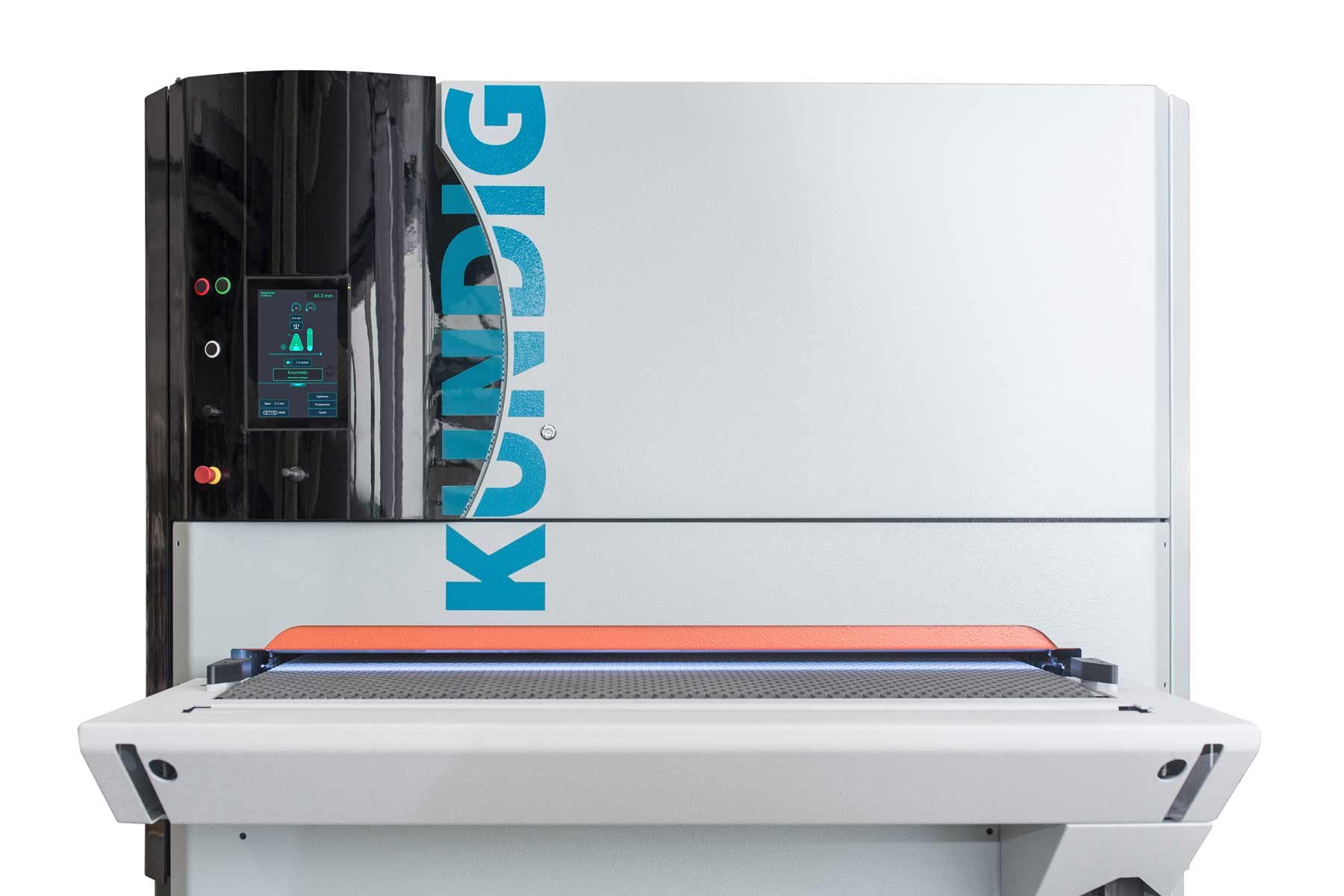

- Touch Operation: All settings, such as the choice of sanding units, feed and sanding belt speed, etc., can be selected on the user-friendly touchscreen and saved as programmes for future use.

Control System Features

- Screens available in sizes ranging from 10 to 19 inches.

- The operating unit can be pivoted from 0° to 90° for flexibility.

- A one-click quick start option.

- A logical, clear, and time-saving interface.

- Remote access via network or cloud.

- Recording of production data, including measurements in m²/ft², workpiece count, and job times.

- USB port for data backup.

- USB port for devices (see below).

- Automatic error diagnosis with guided troubleshooting and error correction.

- Integrated PDF documentation, including wiring diagrams, instructions, and sanding advice.

Note: Specific features and configurations may vary by model.

| Calibration Roller R | Large Calibration Roller G | Segmented Pad E | Combi Unit C | Cross Belt Unit X | Planer Unit F | Brush Unit Bs |

|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

| Calibration Roller | Large Calibration Roller | Segmented Sanding Pad | Unit combining a Roller and a segmented Pad | Machine Body integrated Cross Belt Unit | Planer Unit with different Models available | Brush Unit with different Models available |

For more info on KÜNDIG Perfect belt sanders, see the video below.