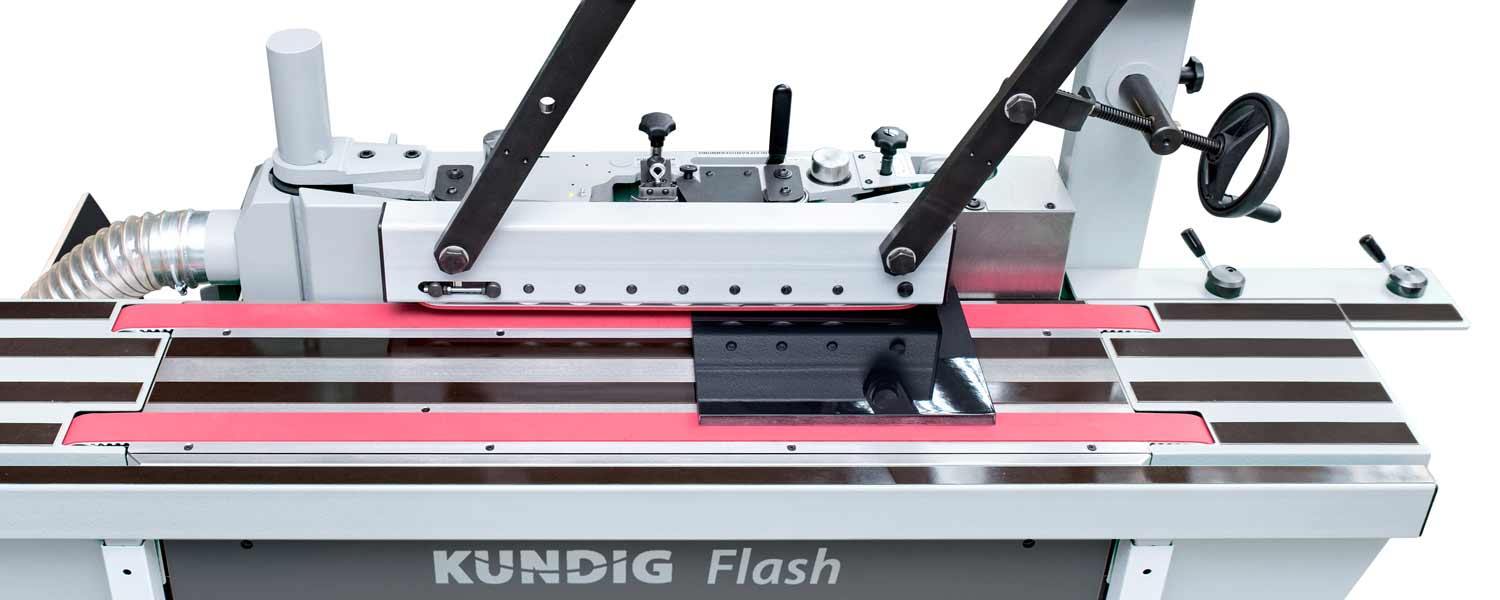

Kündig Flash Edge Sander

The Flash is specially designed for edge lacquer sanding. With the application-controlled, pneumatic sanding pad, belt blow-off jets and variable sanding belt speed, perfect lacquer sanding is achieved, even on high-gloss lacquered edges. The machine is operated via a touch screen which can be rotated by 270°.

TOUCH SCREEN & FEED SYSTEM:

A large part of the operating inputs on the flash are made using the touch screen which can be rotated by 270°. This makes it very easy to adjust oscillation, sanding belt and feed speed, sanding pad insert and release times, as well as storing and recalling sanding programs.

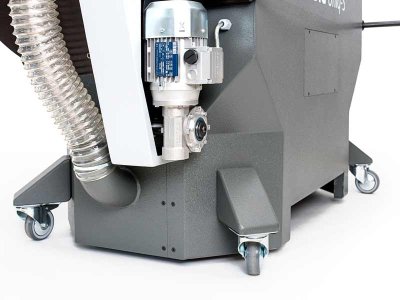

- Machine mobile on casters

- Feed unit and supports

- Veneer sanding along 2 platens

- Entry platen with integrated extraction slits and precise adjustment

- Stock removal against the elastic sanding pad

- Oscillating for an equal consumption of graphite cloth

Besides the touch screen as the most obvious distinguishing feature, the Kündig Flash has many details that make it unique and the first choice for lacquer sanding.

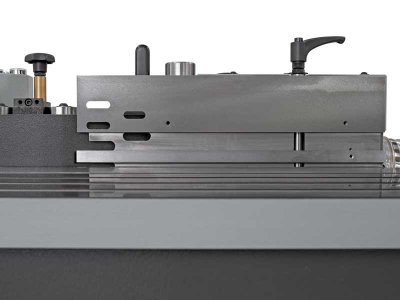

Pneumatic Sanding Pad: Lacquer sanding demands precision, and our action-controlled pneumatic sanding pad is indispensable for this purpose. It ensures that the delicate lacquer layers are not inadvertently sanded through, especially at workpiece corners. To fine-tune the sanding process and tailor it to specific needs, the insertion or removal of the sanding pad can be precisely accelerated or delayed.

Air Jet Belt Blow-off: Leveraging the same extensive oscillation range as our Uniq series, the Flash effectively addresses heat build-up and belt clogging issues. To guarantee optimal performance even when dealing with stubborn lacquer dust, the Kundig Flash comes equipped with an air jet belt blow-off system.

Variable Sanding Belt Speed: While steplessly variable sanding belt speed (3 – 15 m/s, 9 – 45 ft/s) is an option for our Uniq and Uniq-S sanders, it comes standard on our Flash series. This ensures flawless sanding on even the most delicate surfaces.

Advanced Feed System: Our Flash edge sanders include a fully equipped feed system, offering all the advantages of the Uniq-S feed system with additional options. Instead of just one, two rubberized drive belts are integrated into the machine table, and a third one is positioned in the upper pressure beam, effectively replacing the rubberized pressure rollers. This setup guarantees gentle handling of delicate high-gloss workpieces, and the feed speed is also adjustable to suit your specific needs.

FEATURES:

- Motorised height adjustment and tilting of abrasive belt

- Heavy cast iron work table provided on one side for solid wood sanding

- Table 1180x325mm including bevelling fence with scale

- Also provided is a similar one for veneer sanding on the other side

- No adjustment of the working table required

- 400x500mm on oscillating mandrel for sanding bobbins

- Diameter of 25,30,40 & 45 x 100mm for internal and external roundings

- Mandrel protection included

- Sanding unit adjustable in height by motor OF up to 120mm

- Mechanical inclination up to 45 degrees without resetting of tables (patented construction)

- Belt driving motor 3kW (4HP)

- 380 Volts/50 Hz with protective motor switch

- Extra motor for belt oscillation

- Oscillation stroke programmable from 10MM to 90mm

- Electrical case integrated into machine frame

- Constant belt tension with length compensation

- Belt running adjustable

- Contact guard plate

- Dust extraction by 2 suction caps

- Flexible ducts

- Common internal tube & an outlet – dia. 10mm

- Preparation for mounting a support for a feeding unit

- Openings in the frame for easy movement by a forklift truck

- Belt width 150-200mm

- Belt length 2000mm

- Working level approx. 830mm (solid sanding side respectively)

- 900mm (side for veneer sanding)

- Net weight 460kg

- Floor space 1150x800mm

Standard execution Kundig Uniq cost £=POA

Extra tables – £=POA

Q4 Additional cast table with mandrel and 4 sanding bobbins ø25,30,40 & 45 x 100mm

Q5 Semi round table on the driving rollers ø 90mm

Options for all Edge Sanders – £=POA

|

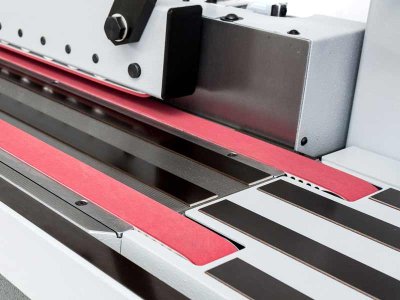

Instead of pressure rollers, the upper feed belt can facilitate the sanding of smaller components

Option for Uniq-S, standard for Flash |

|

For extra wide workpieces an additional lower feed belt can be provided

Option for Uniq-S, standard for Flash |

|

The grooved inlet platen allows the sanding of edges with overlapping veneers

Option for Uniq, Uniq-S, Flash |

|

Semi round table for sanding curved pieces against the rubber covered driving roller

Option for Uniq, Uniq-S, Flash |

|

Extra table with mandrel and abrasive bobbins for external and internal shapes

Option for Uniq, Uniq-S, Flash |

|

Easy handling of large panels thanks to the telescopic support rail

Option for Uniq, Uniq-S, Flash |

|

Increased flexibility and movability thanks to four transport wheels

Option for Uniq, Uniq-S, Flash |

|

Steplessly abrasive belt speed for extremely sensitive surfaces or material with a low melting point.

Option for Uniq-S, standard for Flash |

|

Special sanding pad inserts are available, such as an extra hard sanding pad for extended sanding of solid wooden edges or a ceramic sanding pad for heavy calibration tasks

Option for Uniq, Uniq-S, Flash |

|

Different handling and working table extensions are available, even custom versions

Option for Uniq, Uniq-S, Flash |