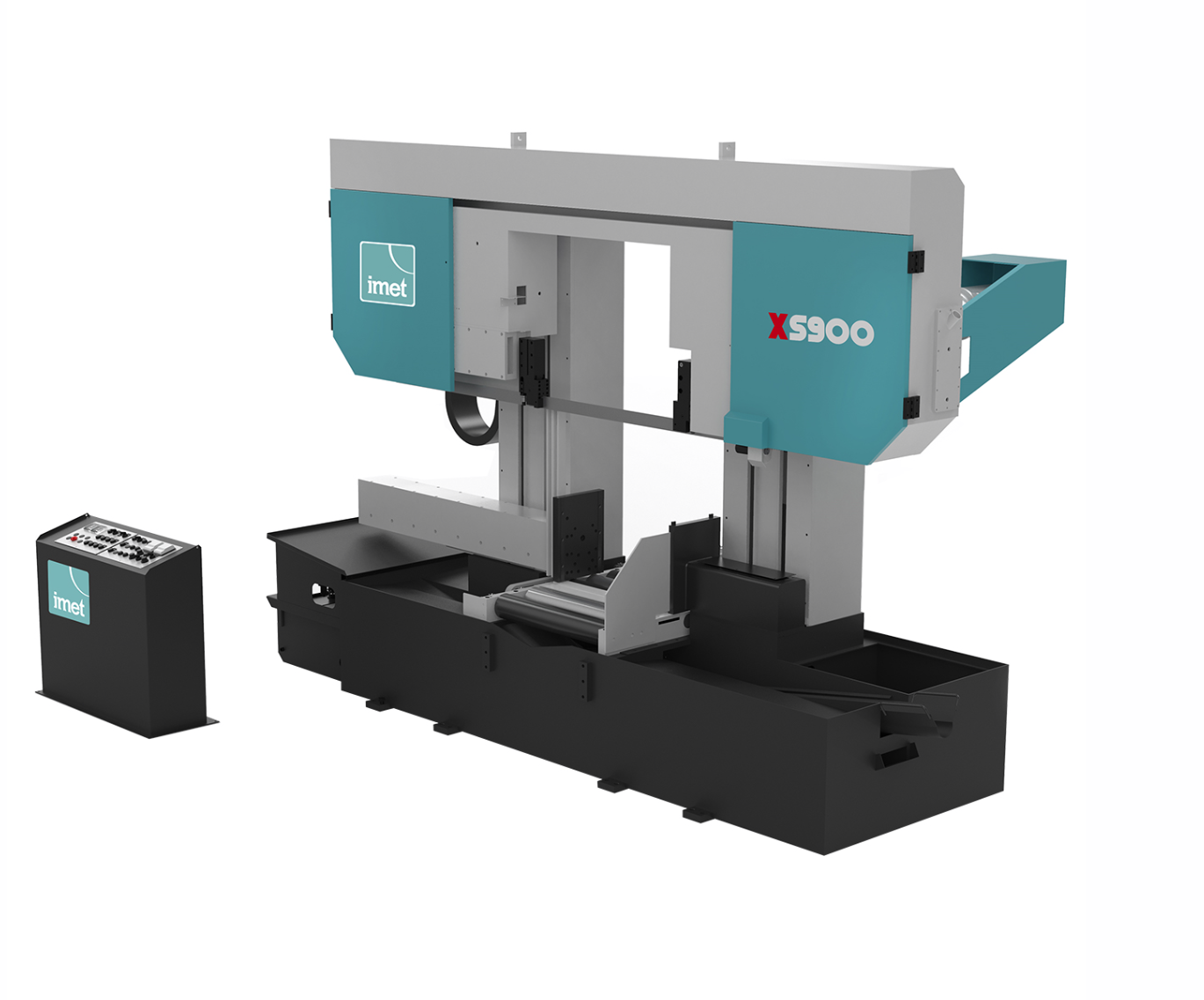

The XS 900 Semi-automatic twin-column bandsaw for cutting large solid materials in a demanding production environment.

Features

Cutting Control: 7″ touch screen HMI with the following functions:-

- Down feed cutting speed

- Blade speed

- Material height (for fast approach and reduced cycle times)

- No of pieces to be cut

Saw Frame: The XS900 features a robust steel saw frame, providing excellent stability and vibration absorption. It is mounted on a large steel column with precision linear guides. To enhance cutting performance, the bandsaw maintains a remarkably high blade tension of 2000kg/cm2.

Structure: To further enhance machine stability and optimise operational efficiency, the machine architecture is constructed using multi-layered heavy steel plates. This design effectively absorbs vibrations and withstands extreme stresses.

Bow Transmission: Blade and bow feeding are controlled by powerful servo motors, accompanied by a control display that provides machine status and error information.

Cutting Table: The machine is equipped with a spacious working area, where seven motorised hydraulic rollers ensure high loading capacity for materials of all sizes. These rollers also contribute to precise material positioning and accuracy. Additionally, the piece is securely held by a horizontal hydraulic vice, optimising the cutting process and improving user workflow.

Blade Guides: The bandsaw employs solid carbide blade guides that are hydraulically tensioned. Furthermore, robust pre-twist roller bearings ensure maximum blade lifespan, accuracy, and precision.

Blade Tension: The blade tension is controlled by a hydraulic cylinder. If the machine remains unused for a certain period, the control system will release the tension on the blade to prevent strain. In the event of a blade breakage, the control system immediately stops the process and displays an alarm.

Chip Conveyor: The XS is equipped with an endless screw type chip conveyor.

Additional upgrades

Micro-mist blade lubrication system

- Is recommended for cutting tubes and sectional materials where loss of flood lubricant through the material is an issue. This precision delivery system allows adjustment for the number of pulses per minute and the quantity of each dose. Please note that this system requires a compressed air supply. The standard flood system is still retained for cutting solid materials, and the operator can easily switch between the two systems.

Imet factory fit powered laser line.

Optional quality German laser line

Blade Deviation Control

- The blade deviation control allows for maintaining perfect alignment and blade position at all times. Additionally, it features automatic detection and stops the cutting process in case of blade breakage.

Roller Tables

Loading/unloading roller table

- Loading and unloading roller table with freely rotating rolls and compatible with a measurement system. It consists of a single module that is 2 metres long.

Roller table prepared for motorization (Optional)

- Roller table with all transmission elements for motorisation. Chain with pinion gears.

Motorisation system (Optional)

- Motorisation system for motorised roller table, recommended every 6m length.