Imet Ktech 1202 F3000 & 6000

This machine comes highly recommended for production cutting of structural sections. The inclined saw blade provides the line of least resistance on square section materials, resulting in faster cutting times, longer blade life, and increased scope for each tooth pitch. This also reduces stress on the machine components. It is available with a 3m or 6m incremental feeder.

- The arc in electro-welded steel with a thick section guarantees the absolute lack of vibrations.

- The movement of the bow is perfectly balanced and guaranteed by the large diameter hydraulic cylinder.

- The numerical control allows to set and store over 90 cutting programs, with different quantities, lengths and angles.

- Programming keyboard integrated with CNC, positioned on mobile console, LCD display for visualization of work phases and self-diagnostics.

- The rotation of the arc takes place on large preloaded bearings by means of a geared motor and a self-braking motor with encoder for reading the position. Automatic locking of the arc rotation is hydraulic.

- Hydraulic vertical pressure to optimize the blocking of the material and avoid vibrations during cutting (Optional).

- Blade refrigeration with minimal standard lubrication, to make cuts on sections and pipes without the inconvenience of dispersion of the traditional liquid typical of cuts on relevant lengths.

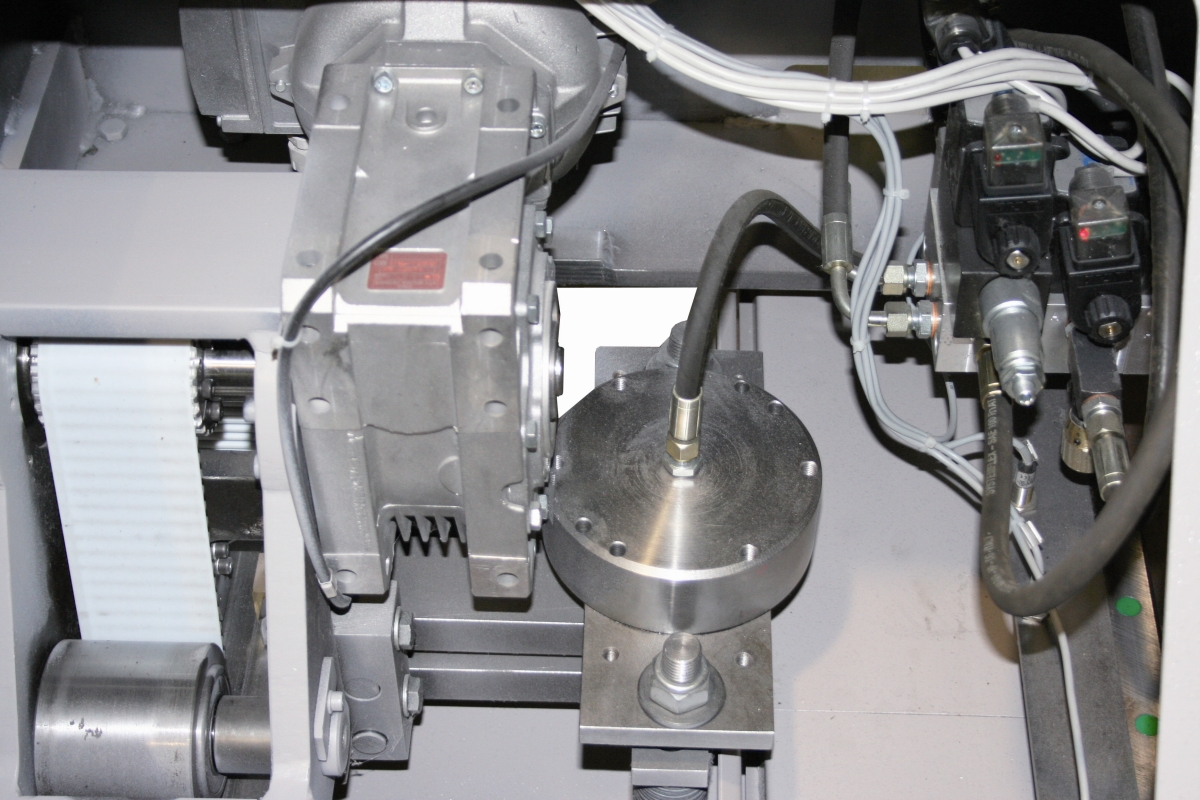

- Hydraulic power unit with energy saving as standard, during cutting and in phases where no hydraulic pressure is needed, the control unit switches off, thus guaranteeing considerable energy savings.

- Cut to 90 °: round 520 mm., Square 450 mm., Rectangle 680 x 400

Technical Data:

| Cutting capacity at 90° | Round: 680mm Square: 640mm Rectangular: 1250x600mm |

| Cutting capacity at 45° (light) | Round: 680mm Square: 600mm Rectangular: 870x600mm |

| Cutting capacity at 45° (right) | Round: 680mm Square: 600mm Rectangular: 840x600mm |

| Cutting capacity at 60° (left) | Round: 580mm Square: 530mm Rectangular: 550x450mm |

| Cutting capacity at 60° (right) | Round: 550mm Square: 450mm Rectangular: 550x450mm |

| Cutting capacity with bundle device | Max: 1000x350mm Min: 80x80mm Scrap-end: 400mm |

| Cutting capacity at 90° (solid C45) | 400mm |

| Blade size | 8140x54x1.6mm |

| Blade tension | 3000kg/cm2 |

| Blade speed | 18 90 m/min |

| Blade motor power | 7.5KW |

| Feeder length | 3000mm with automatic repetition |

| Minimum scrap-end | 400mm |

| Cutting length | 6 9.999mm |

| Feeder motor power | Asynchronous with inverter |

| Size – Weight | 5750x4200x2750mm (h 850mm) 4800kg |

Features:

Cutting Control:

The KTECH 1202 features an easy-to-use interface dedicated to optimizing the user experience. With the CNC system and a 10″ touch screen display, the user can manage all machine functions, set up to 99 cutting programs with multiple cutting lengths on the same bar, adjust the number of feeder strokes, pieces, and blade speed. The machine also includes a diagnostic program.

Material Ejection System: This system is facilitated by the feeder advancing the piece and then retracting to perform the next cut. The material ejection system offers three options:

- No ejection

- Ejection of trim cut only

- Ejection of all pieces

Automatic Cutting Program:

The graphical software displays the programmed job, clearly showing angles and piece dimensions. This reduces errors and simplifies the compilation of complex cutting lists.

Feeder as Length Stop:

The feeder can be used as a length stop during semi-automatic cutting cycles. By using the GO TO option, the feeder can be set to the required length (minimum 270 mm, maximum distance between the blade and feeder). In this case, the bar will be loaded from the unloading side, and the feeder vice will be fully closed to serve as a length stop.

4 Controlled Axes:

KTECH automatic bandsaws feature an innovative 4 controlled axis system (lateral movement and closing of the vice, material feeding, and saw frame rotation), all managed by numeric control. All machine movements and settings can be controlled and modified via the touch screen display.

Saw Frame:

The KTECH NC model is intentionally built with extra heavy steel material to absorb vibration, enhance structural stability, and enable high band tension (2000kg/cm2). This design ensures maximum accuracy and cutting performance. The blade is inclined by 5° to improve cutting efficiency on square section and flat plate materials.

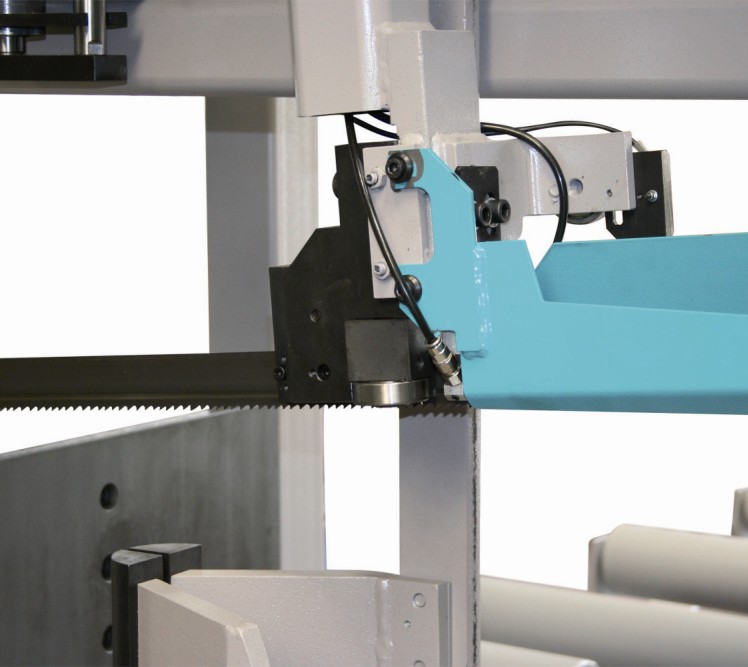

Head Rotation:

The automatic saw frame rotation is managed by a powerful servo motor, reduction gearbox, and inverter. A hydraulic piston locks the bow once it reaches the set position. To maintain clean transmission elements and reduce maintenance, an air-cleaning system is activated during the rotation. The bow rotation power is 0.55KW.

Blade Speed:

KTECH’s blade drive is equipped with an electronic inverter to expand the blade speed range (from 18 to 100 m/min), allowing optimal cutting performance on a wide range of materials while also extending blade life. For effective cutting on wider sections and solid materials, the blade has high tension (2000kg/cm2).

Height Detection:

The mechanical material detection system automatically detects the precise material height, enabling fast bow approach to the material and triggering the selected cutting speed. The end-point is detected by a microswitch placed on the mobile blade guides, which identifies when the cutting process ends.

Vice:

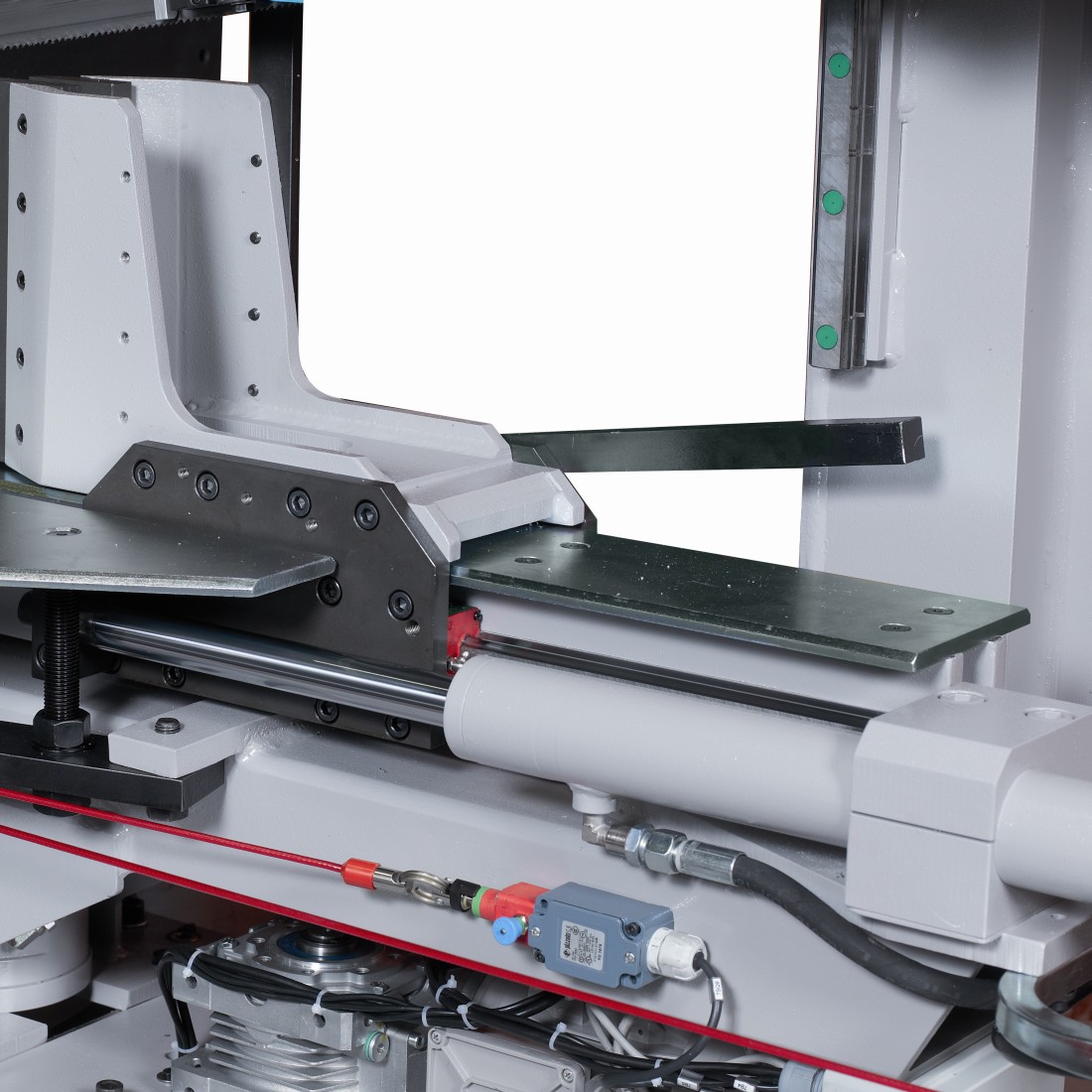

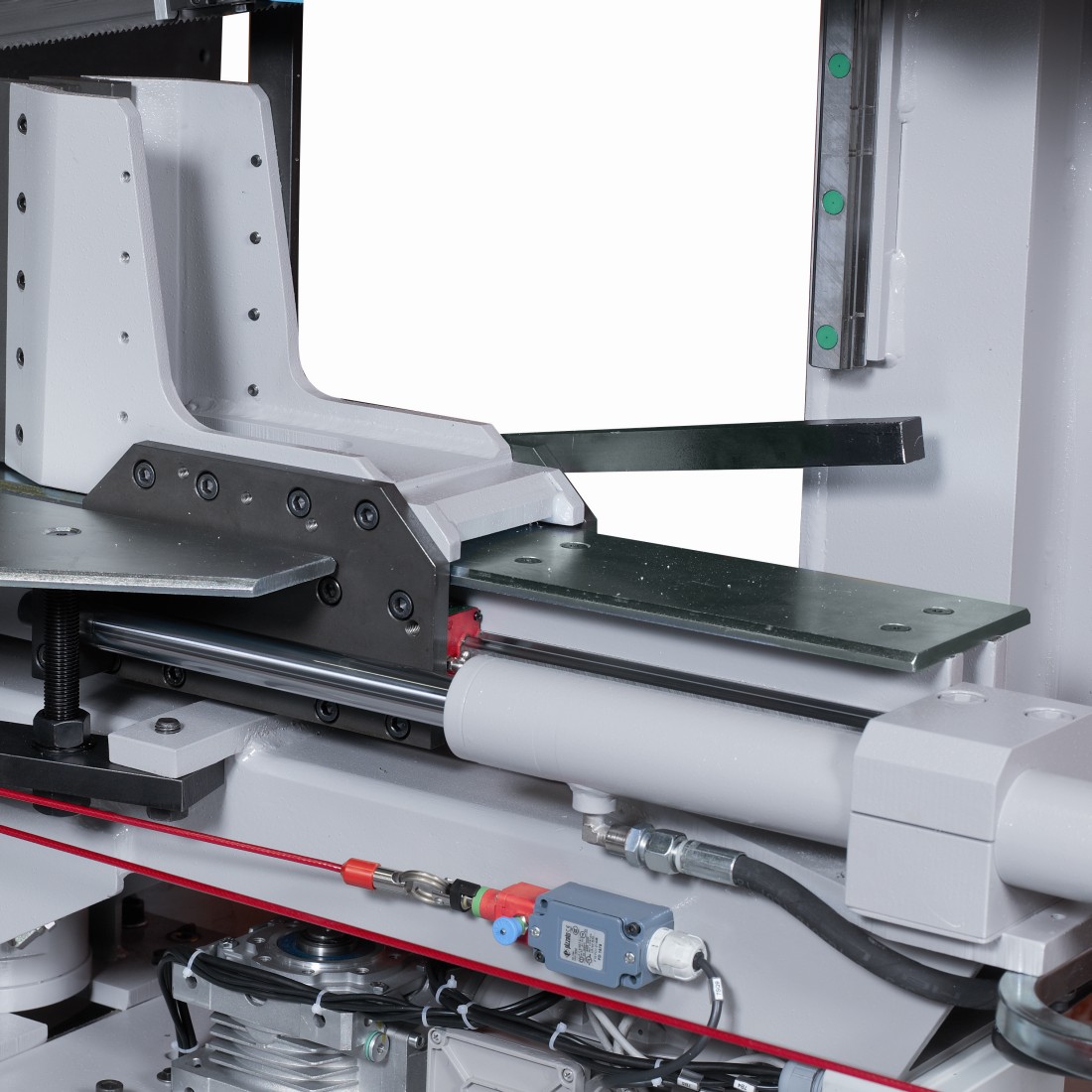

The horizontal vice features round jaws, allowing the material to be locked at any set angle. This design ensures the material is secured as close as possible to the cutting line on both sides of the bar, facilitating the cutting process at any angle. The jaw height is 370mm.

Feeder:

The KTECH comes with an integrated feeder that includes an integrated roller table with a length of 3000mm. Feeder movement and repetition can be set via the touch screen display. The cutting material is fully supported by the roller table, while the final scrap-end measures 150mm.

Standard Minimal Lubrication:

The machine is equipped with a standard minimal lubrication system to prevent coolant dispersion and keep the working area perfectly clean, ensuring the machine operates efficiently. The system includes an automatic switch, two nozzles, and a 1.3-liter tank capacity.

Inclined Blade:

To enhance material penetration on square section and flat plate materials, the blade is inclined

Optional Equipment *:

*These items can be added to your quote. Contact us for more technical details

Marking System:

For KTECH models, there is an optional automatic ink marking system available. This system enables the marking of a code on cut pieces, facilitating material selection after the cut. The marking system operates before the cut and its programming is integrated with the machine’s CNC. A unique program can be created via the KTECH touch screen. Additionally, the marking system is equipped with its own independent touch screen display.

Blade Deviation Control:

The blade deviation control ensures precise cutting processes by maintaining the right tolerance. The selected tolerance can be adjusted based on the specific material or cutting angle requirements. The maximum tolerance allowed is 0.2mm.

Bundle Vice:

The KTECH 1202 can be equipped with a hydraulic bundle cutting device. By applying this device, the maximum and minimum cutting capacity is modified as follows: maximum size of 1000x320mm, minimum size of 80x80mm, and a minimum cut length of 400mm.

KTECH rollersLoading / Unloading Roller tables with rollers, complete with measurement system. Please contact us for more technical details. |